Introducing Butyl Rubber |Aquasky

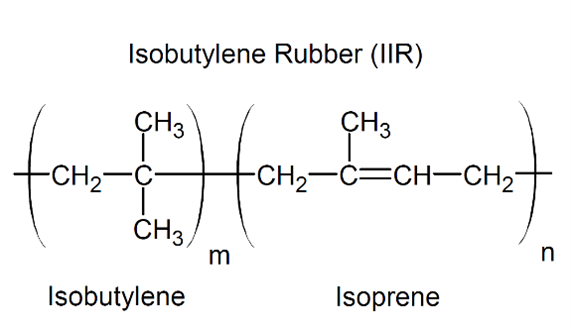

Butyl rubber, also known as Isobutylene-isoprene (IIR), is a synthetic rubber, a copolymer of isobutylene with isoprene. The abbreviation IIR stands for isobutylene isoprene rubber. Butyl rubber is produced by polymerization of about 98% of isobutylene with about 2% of isoprene. Structurally, polyisobutylene resembles polypropylene, but has two methyl groups substituted on every other carbon atom, rather than one. Polyisobutylene is a colorless to light yellow viscoelastic material. It is generally odorless and tasteless, though it may exhibit a slight characteristic odor.

Butyl elastomers can be vulcanized with sulfur. However, the low level of unsaturation requires more active accelerators such as dithiocarbamate and thiuram. Put simply, vulcanizing is a process that ties all the rubber molecules together to form a single large molecule that does not melt as it gets warm and does not embrittle as it gets cold. It is a thermosetting process, so vulcanizing takes place after the product is formed.

Butyl has outstanding resistance to attack by oxygen and ozone, and good chemical resistance to a large number of organic and inorganic media. Due to the absence of double bonds in the backbone, IIR products can withstand prolonged exposure to heat, and are usually stable in dilute acids and alkalis. It has good shock absorption characteristics and low moisture and gas permeability and is used in many commercial applications.

Butyl rubber is the only known elastomer that is impervious to gases. The material is flexible, with good room temperature damping characteristics. The material is biocompatible, resists many acidic and alkaline chemicals, ozone, heat, and weathering, and has good aging properties. It resists attack by phosphate ester hydraulic fluids and ketones but does not do well in the presence of mineral or petroleum-based fluids, hydrocarbons, or flame. It has good electrical insulating properties. The typical working temperature range of butyl rubber products is -50°C (-25°C) to +120°C, but its damping characteristics diminish at higher temperatures. It remains flexible at lower temperatures.

A summary of butyl rubber’s mechanical strengths and weaknesses include:

Compression set: fair

Rebound rating: poor

Flex cracking resistance: good to excellent

Abrasion resistance: good to excellent

Tear resistance: good

Impact resistance: good

Flame resistance: poor

Weather resistance: excellent

Sunlight resistance: excellent

Ozone resistance: excellent

Oxidation resistance: excellent

Water resistance: very good

Steam resistance: excellent

Gas permeability: good

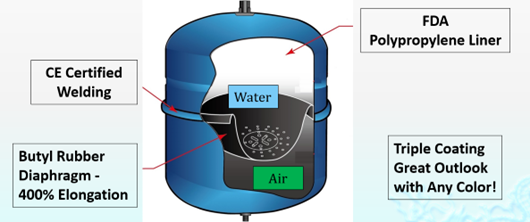

Butyl rubber has unique elastomeric properties that makes it a good choice for a wide variety of rubber goods. Its low gas permeability with flexibility makes it the ideal material for inner tubes of tires and other high-pressure tubes. Other applications include diaphragms, gaskets, wire and cable insulations, liners, O-rings, seals, weather stripping, and bottle closures. It’s very low resilience makes it also suitable for shock absorption, vibration damping and insolation applications. Lower molecular grades find uses in pressure-sensitive adhesives, hot melts, caulks, and sealants. Products formulated with butyl rubber have improved chemical and heat resistance.

With these advantages, Aquasky also uses this material in the diaphragm of the pressure tank, it is extremely resistant to bacterial growth and meets FDA requirements for potable water supply.

If you have any further question, please feel free to contact us.

E-mail: [email protected]