What is the difference between a relief valve and a safety valve? |Aquasky

Both safety valves and relief valves are used to release pressure from a pressurized system. Both are pressure relief valves, and they are designed to let off pressure in any situation where a system becomes overpressurized. But relief valves and safety valves do function slightly differently:

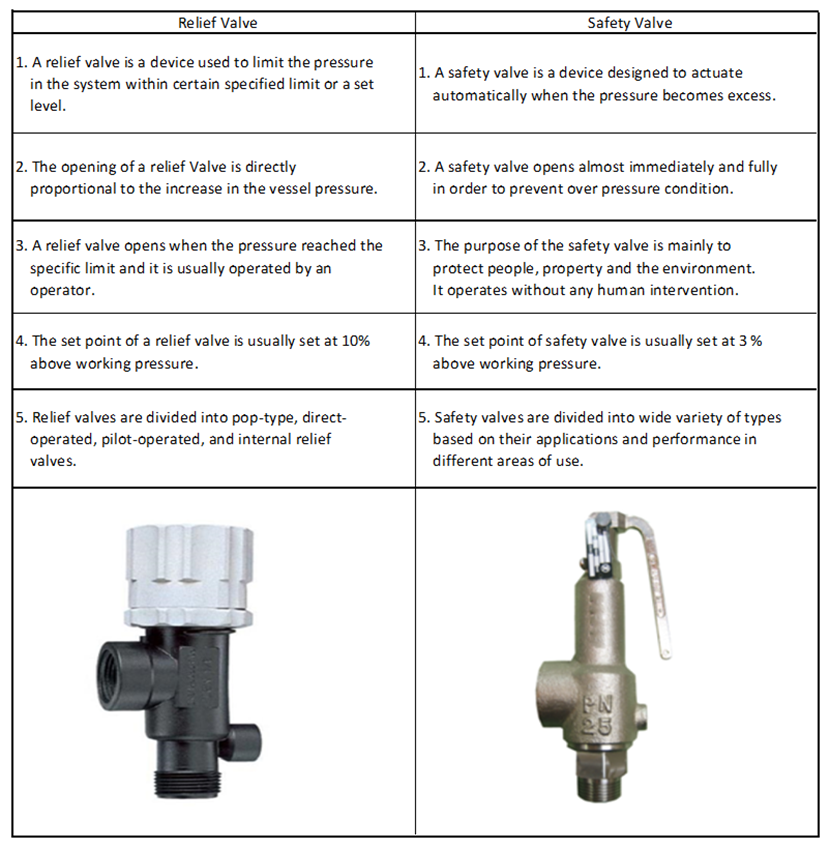

Comparison table:

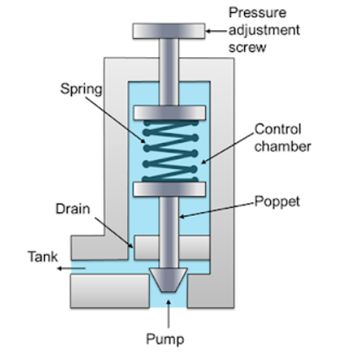

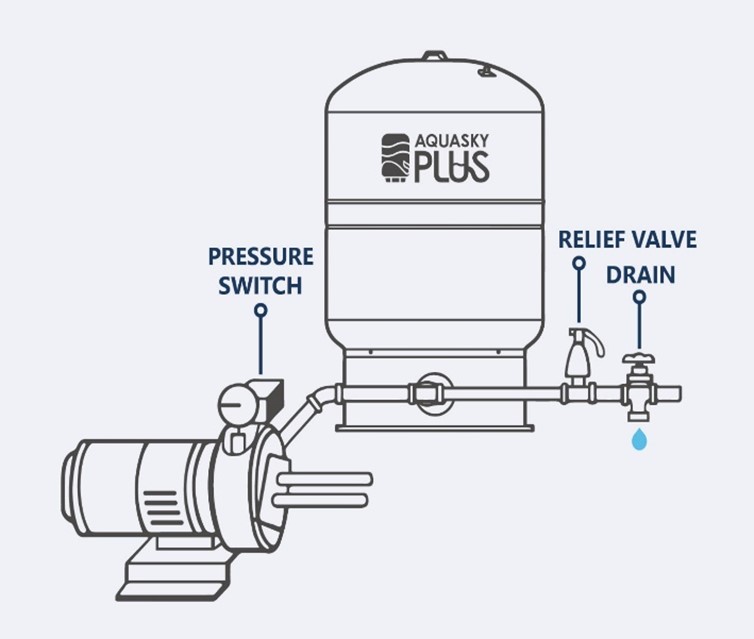

Pressure relief valves protect pressure tanks and other equipment from catastrophic failure if the pressure in the system exceeds safe limits. Pressure relief valves relieve pressure by opening at a set pressure to exhaust air or water when normal operating controls fail or during abnormal system conditions. It is also a safety device that comes into use for maintaining the pressure of a system at a specific level so that overpressure conditions do not occur. The device does not allow the pressure to rise above the setpoint.

The above information to share with you.

Aquasky offers high-quality pressure tanks and customized services worldwide.

Please contact Aquasky for any needs. E-mail: [email protected]