How does PP Liner work in a Diaphragm Pressure Tank?

There are several types of pressure tanks in the water industries, and the diaphragm type pressure tank has the market highest standard of the best design type of pressure tank. The failure rate is very low and the lifetime is extremely long.

Diaphragm pressure tanks consist of two separate chambers: one for compressed air and the other for water. A rubber diaphragm is permanently attached to the sides of the tank to separate water from the air. It rises and falls with the water level. As water is pumped into the tank, the diaphragm is pushed up to the compressed air chamber which then triggers a sensor to shut off the pump.

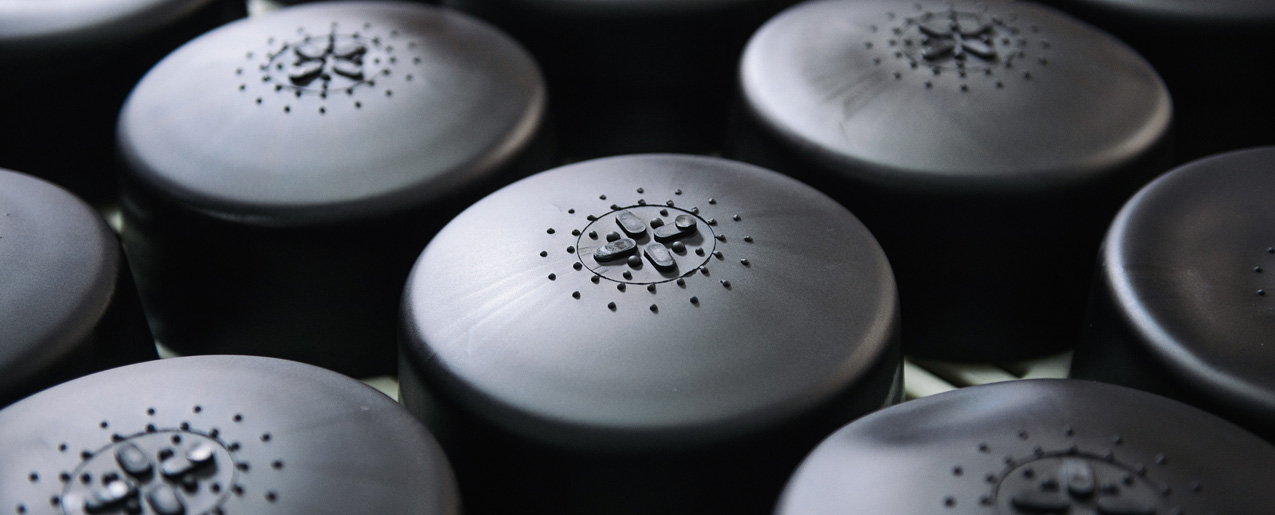

For the water chamber, Aquasky uses food-grade Polypropylene to make a thin liner. The polypropylene material has been certified by the USA NSF standard and ACS France standard. The polypropylene is injected into a designed mold and forms into a shape.

The liner has the same shape as the tank shell with a smaller diameter which can be installed perfectly into the water tank. The liner and the diaphragm create a water storage zoom in which the water inside the tank does not contact the steel tank shell. No rusty and no water pollination. The tank shell can keep the strength as the original steel has to hold the water pressure inside the tank.

There are some diaphragm tanks are made with an epoxy powder coating layer inside the tank to create the water zoom. After these tanks are in the water service for a while, the water flow dynamic force and the water temperature can cost the coating layer to peel off. The water contacts with the tank shell creating rusty, and the tank failed.

Only very few manufactories in the world are able to produce the diaphragm tank with a PP liner, and Aquasky is one of the best.